Aviation is embracing new digital tools to improve how aircraft are built, maintained, and tracked over time. Aviation digital twins – virtual replicas of aircraft or components that mirror real-world conditions – are increasingly used to monitor performance and predict maintenance needs. At the same time, blockchain technology is emerging as a solution for securing aircraft lifecycle data and maintenance records across multiple stakeholders (OEMs, MROs, airlines, lessors).

When combined, digital twins and blockchain can transform how the industry manages the complete lifecycle of aircraft assets, from manufacture ("birth") to retirement. This article explores what digital twins mean in an aviation context, how blockchain complements them by providing an immutable record of events, and the benefits of this synergy for asset integrity, predictive maintenance, regulatory compliance, and resale value. We also highlight real-world examples – from Boeing and Rolls-Royce to GA Telesis and startups that are pioneering these innovations.

What Are Digital Twins in Aviation?

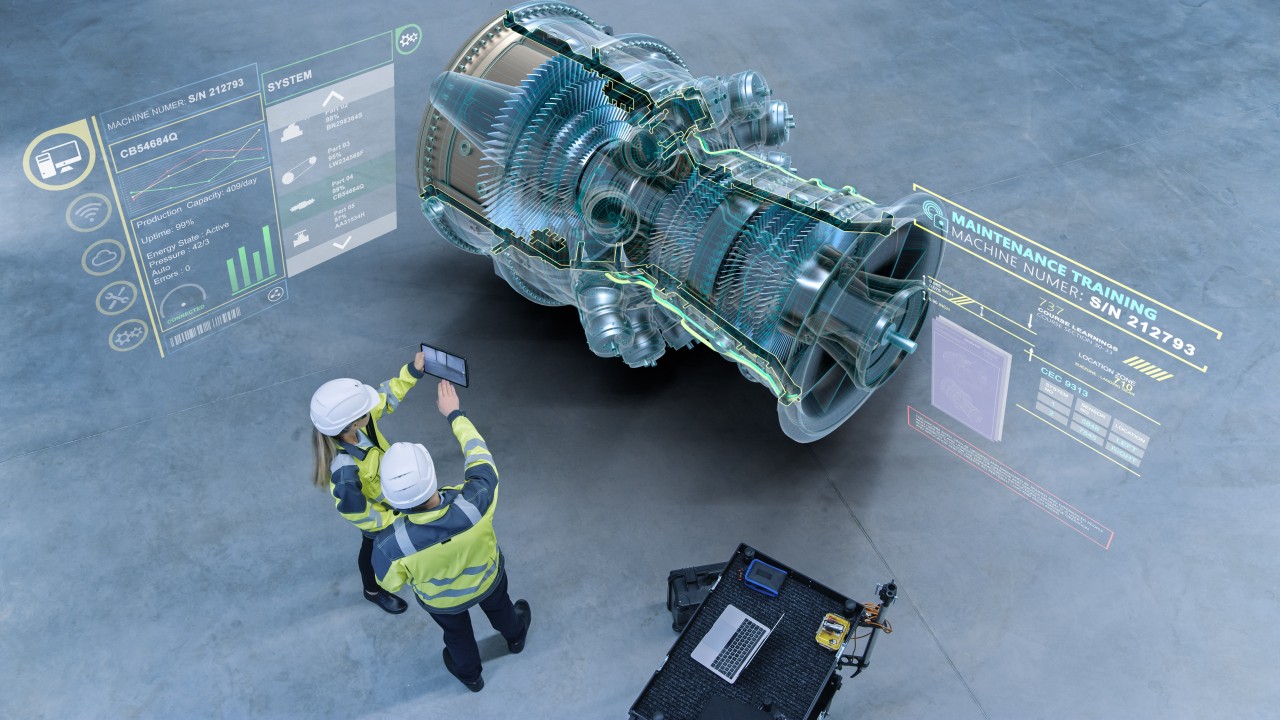

In aviation, a digital twin is a highly detailed virtual model of a physical asset, such as an entire aircraft or a specific component (like an engine). This model is continuously fed with real-time sensor data and operational information, allowing it to behave exactly as the physical object does. Essentially, the digital twin serves as a live replica, reflecting the aircraft's current condition, performance, and environment.

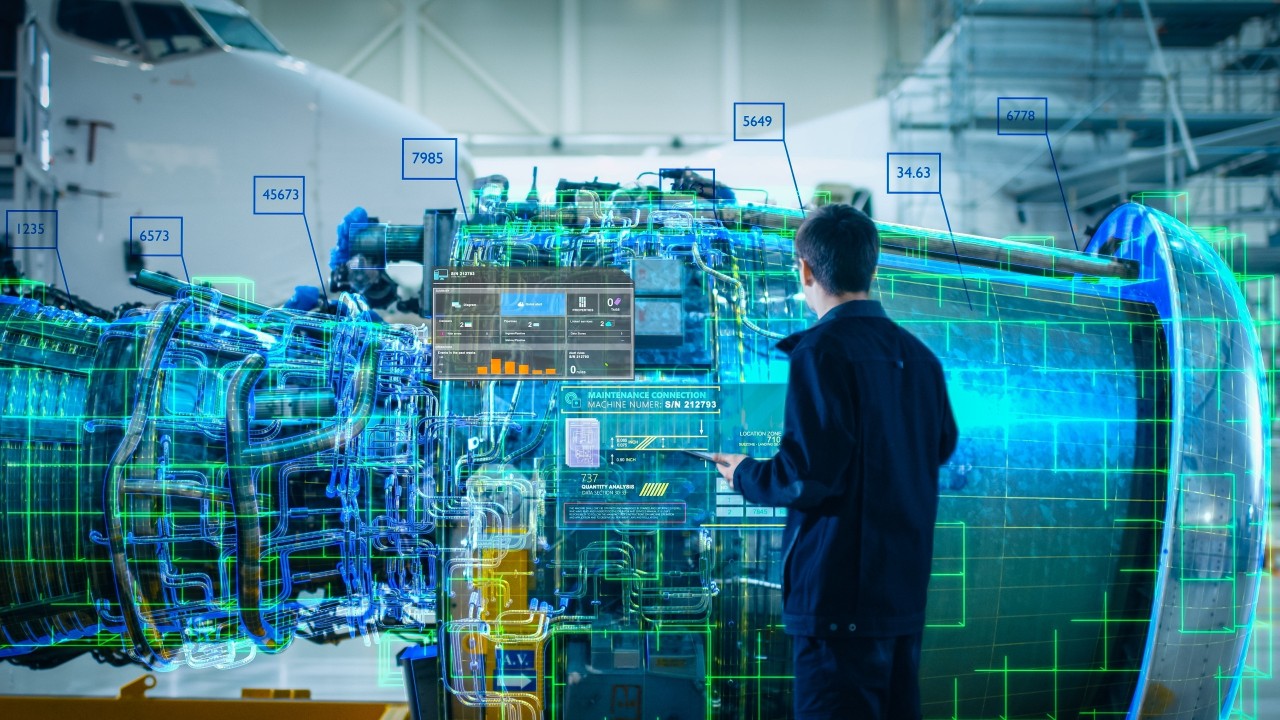

For example, Rolls-Royce creates digital twins of jet engines with onboard sensors streaming data via satellite to the virtual engine model in real time. The twin "runs" in parallel to the real engine, enabling engineers to see how the engine is operating and even predict when it will need maintenance. This approach allows for predictive maintenance – identifying issues before they cause downtime – and preventative actions to be taken to avoid unexpected failures, which greatly reduces aircraft downtime and enhances reliability.

Digital twins are a cornerstone of aviation's Industry 4.0 transformation, merging the digital and physical worlds. They leverage data analytics, machine learning, and IoT (Internet of Things) sensors to simulate different scenarios and stress conditions without risking the actual aircraft. Some key benefits noted from digital twin deployments include:

- Accuracy: The twin continuously learns from real-world data and updates itself, ensuring it accurately reflects the asset's condition in real time.

- Early Fault Detection: Anomalies or performance issues can be flagged in the digital model before they become critical, minimizing operational disruptions.

- Extensive Testing: Engineers can run simulations on the digital twin (e.g. extreme environmental conditions or different usage profiles) to see how the asset would behave, far beyond what physical tests alone can cover. This helps understand long-term performance across an engine's lifetime, even under varied airline operating conditions.

- Extended Lifespan: Insights from the twin can optimize maintenance schedules, increasing time-on-wing for engines and extending component life by as much as 70% in some cases.

- Optimized Maintenance Planning: With up-to-date knowledge of an asset's health, maintenance can be accurately planned and timed, ensuring the right parts and technicians are ready exactly when needed.

In short, digital twins provide aviation professionals with a powerful tool to monitor and manage assets proactively. However, their effectiveness depends on the quality and completeness of the data they receive throughout the aircraft's lifecycle. This is where blockchain comes into play.

Blockchain's Role in Aircraft Lifecycle Data

Blockchain is essentially a distributed ledger technology – a way to record transactions or data changes across a network in a secure, tamper-proof manner. Once data is recorded on a blockchain, it becomes extremely difficult to alter, as each record (or "block") is cryptographically linked to the previous one, forming an immutable chain.

In the context of aviation maintenance and asset management, blockchain can serve as a single source of truth for an aircraft's history. It enables recording every event in an aircraft or part's life – from manufacturing and certification to maintenance actions, part replacements, and beyond – in a shared, indelible record.

One major challenge today is that aircraft maintenance records and part histories are fragmented across different IT systems and often still paper-based, making it hard to trace the provenance of each component. According to Boeing, tracking the life cycle of thousands of aircraft parts and ensuring the accuracy of that information is a "huge challenge" in the industry. Blockchain directly addresses this by providing an "error-free data exchange" that all authorized parties can trust.

In a blockchain-based system, whenever a part is manufactured, installed, inspected, repaired, or removed, a digital record of that event (with timestamp and details) is added to the ledger. Because the ledger is shared among participants (OEMs, airlines, MROs, lessors, regulators), everyone with permission sees the same tamper-proof history of the asset.

Notably, no single entity can unilaterally modify or falsify the records on a blockchain. This builds cross-organizational trust. For example, Boeing has explored using IoT sensors and blockchain to capture complete provenance details for each component part, making this information accessible to the manufacturer, the airline (owner/operator), maintenance providers, and regulators alike. The goal is to improve data trust and transparency across the aviation ecosystem.

In Boeing's vision, such a system would bolster operational efficiency by reducing data silos and ensuring that every stakeholder – from a parts supplier to an airline's engineering team – is referencing the same verified data about a component's status and history.

Another powerful feature of blockchain is smart contracts – self-executing code that runs when certain conditions are met. Smart contracts can automate business rules and maintenance procedures. For instance, a smart contract could automatically verify if a part's overhaul is due based on usage data from the digital twin and then log a service event or alert the MRO when thresholds are reached.

Blockchain can also tokenize physical assets, essentially creating a unique digital token for each part or aircraft that serves as its digital identity or "pervasive digital twin" on the ledger. This tokenization, combined with the ledger's provenance tracking, means every time an asset changes hands or status, the blockchain records who, what, when, and where in a permanent trail. The result is a trusted chain of custody and configuration data for the asset, which is invaluable in aviation where safety and compliance are paramount.

Combining Digital Twins and Blockchain for Full Lifecycle Management

While digital twins provide a live mirror of an asset's condition, blockchain provides the memory – an immutable log of all states and events in the asset's life. Together, they create a comprehensive, trustworthy picture of an aircraft's lifecycle.

The digital twin uses real-time data (e.g. sensor readings, flight parameters) to predict and model current and future performance. Blockchain complements this by recording key lifecycle events (e.g. part installed or removed, maintenance performed, software updates applied) in a way that can be securely shared and audited.

For example, imagine an airline using a digital twin to monitor an aircraft engine's performance. When the twin predicts an impending wear issue on a turbine blade, a work order is generated. Once the blade is replaced, that event (with part serial number, time, and technician ID) is written to the blockchain. The updated data flows back to update the digital twin's model of the engine.

Now the twin "knows" the engine has a new blade and can continue forecasting based on the part's expected life, and the blockchain has a permanent record of the swap. If the aircraft is later sold or leased out, the new owner can query the blockchain record to see that this engine had a blade replaced at a specific time, by an authorized technician, using an approved part – all verified.

In essence, blockchain assures the integrity of the data feeding the digital twin, and the digital twin provides meaning to the data on the blockchain by using it for live analysis and predictions.

Blockchain's distributed ledger also enables cross-company data sharing for an aircraft's digital twin. A commercial airliner's lifecycle typically involves many actors: the manufacturer, perhaps multiple airline operators, maintenance providers in different regions, lessors, and eventually a buyer in the second-hand market.

Traditionally, important data (like repairs or modifications) might be lost or delayed in handovers between these entities. With a blockchain-backed digital twin, whenever the aircraft or one of its major components undergoes a change, all authorized parties see the update. This ensures that the digital twin remains an accurate reflection of the asset despite organizational boundaries.

It also means an audit trail is automatically built. Regulators or safety investigators, for instance, could retrieve a trusted history of the aircraft's configuration at any point in time. In fact, one aviation blockchain provider noted that the timestamped records enable creating a digital twin of any aircraft at any point in its life for analytics and part forensics.

This capability is extremely valuable for examining incidents (by reconstructing the exact state of the aircraft at that time) or proving compliance retrospectively.

Boeing's early experiments demonstrated this synergy: by integrating blockchain-stored data with an aircraft's digital twin, they created a comprehensive view of the asset's state, helping anticipate and mitigate problems before they occur. In practice, Boeing found that IoT sensors plus blockchain plus digital twin models could reduce unexpected maintenance events by improving data quality and predictive analytics.

The main value proposition cited was fewer outages and unplanned repairs, since the digital twin can warn of issues and the blockchain ensures all maintenance data is reliable and up-to-date across the ecosystem.

Benefits of the Digital Twin–Blockchain Combination

The fusion of digital twins with blockchain yields several key benefits for aviation stakeholders throughout an aircraft's lifecycle:

Enhanced Asset Integrity & Data Authenticity

Every change or event in an asset's life is logged to an unalterable ledger, providing a tamper-proof lineage of the aircraft or part. This assures that the digital twin's data reflects the true configuration and usage history of the asset at all times. OEMs, airlines, MROs, and regulators can trust that no maintenance record or part transaction has been falsified or omitted.

Boeing's approach showed that complete part provenance details recorded on blockchain could be shared among manufacturers, operators, and regulators, instilling confidence in the data. For the industry, this means no more missing logbooks or ambiguous paper trails – the asset's integrity is verifiable, which ultimately enhances safety.

Predictive Maintenance & Lower Downtime

With higher-fidelity data feeding into digital twins, airlines can predict maintenance needs more accurately and avoid unexpected failures. Blockchain ensures the twin is informed by all relevant events (e.g. part replacements done by a third-party MRO), enabling better analytics. The result is more timely interventions and reduced AOG (aircraft on ground) incidents.

Boeing has noted that using blockchain-backed data with digital twins can help anticipate problems before they occur and thus reduce outages and unplanned maintenance. In practice, airlines can schedule repairs at optimal times instead of reacting to breakdowns.

Rolls-Royce's engine digital twins already predict when an engine will need attention, and by acting on those predictions, operators greatly minimize downtime and keep aircraft flying longer. Combining that capability with an immutable maintenance log adds assurance that the necessary preemptive actions were taken and recorded properly. Overall, predictive maintenance becomes more reliable, translating to higher fleet availability and lower maintenance costs.

Streamlined Compliance & Auditing

Regulatory compliance in aviation is rigorous – every critical part and maintenance task must be documented and verified. A blockchain ledger serves as an instant audit trail of an aircraft's compliance with maintenance schedules, airworthiness directives, and component life limits.

Since entries are time-stamped and tamper-evident, auditors can rely on the blockchain records to quickly verify that inspections and replacements were performed at required intervals. This reduces the manual effort of aggregating records from various sources during audits.

Airlines can demonstrate compliance to authorities with a few clicks, and lessors can more easily assess if an aircraft meets return conditions. In a blockchain-enabled maintenance network, even regulators could be permissioned to view certain data in real time, rather than waiting for operators to compile reports.

Additionally, digital certificates of airworthiness or part certifications could be managed on-chain to prevent any risk of counterfeit or expired documents. The net effect is faster, more transparent compliance checks and a higher level of safety assurance.

Higher Resale Value & Easier Transitions

When an aircraft or engine is sold or leased, having a complete, trustworthy service history significantly improves its value and liquidity. A buyer or leasing company typically conducts extensive due diligence on maintenance logs to ensure the asset was properly cared for.

With a blockchain record, the entire back-to-birth history is readily available and cryptographically authenticated, reducing uncertainty. This transparency can command higher resale prices and smoother transactions.

For example, one recent industry blockchain initiative enabled Air France–KLM's MRO to trace every part on a Boeing 787 from its birth through all removals and installations. The partners noted that by leveraging blockchain, they ensure complete transparency and traceability, giving customers and lessors confidence in part authenticity and condition.

In the future, an aircraft coming off lease could be delivered with a digital logbook secured by blockchain, which the new operator or owner can trust without lengthy verifications. This not only preserves asset value but also reduces transition costs and time (for instance, lessors can avoid penalties or value reductions due to missing or suspect records).

Ecosystem Efficiency & Collaboration

Beyond the specific points above, there is a broader benefit – improved collaboration among all aviation stakeholders. Blockchain's shared data environment breaks down information silos. OEMs, suppliers, airlines, and maintenance providers can work off a single source of truth, reducing miscommunications and duplicate record-keeping.

This can optimize inventory management (knowing exactly which parts are where and their status), enhance warranty and insurance processes (with provable records of how a part was used), and even enable new business models like usage-based contracts or integrated fleet support.

A blockchain-based network essentially creates a "self-healing" data fabric for the industry: if a part goes through a period where data isn't captured (for example, handled by a party outside the network), the next time it enters a blockchain-participating facility, the gap is closed by updating the ledger. Over time, as more participants join, the system becomes more robust and valuable for everyone involved.

Real-World Pioneers and Pilot Projects

This convergence of digital twin and blockchain technology in aviation is already moving from concept to reality. Several industry players have launched pilot projects or solutions demonstrating the potential:

Boeing

The aircraft manufacturing giant has been exploring digital threads and blockchain to enhance its operations and services. Boeing engineers have discussed how an IoT-driven blockchain system could track the entire life cycle of an aircraft's parts, feeding data into digital twin models to improve maintenance forecasting.

In one presentation, Boeing showed a four-phase aircraft lifecycle ("design & build", "operate", "maintain", "dispose") and highlighted that thousands of parts and steps are involved – a complexity that blockchain can help manage by providing a unified, trusted data repository. Boeing's Robert Rencher noted that improving "trust in data utilization across the ecosystem" is key, and blockchain is a tool to bolster that trust.

While much of Boeing's work in this area has been exploratory, it underscores a top-down recognition of the value in marrying digital twin data with a secure ledger to reduce inefficiencies and unplanned downtime in airline operations.

Rolls-Royce

The engine manufacturer has been a leader in adopting digital twin technology to monitor engine health. Every new Rolls-Royce jet engine comes with a digital twin that updates continuously with performance data, enabling Rolls-Royce and airline customers to predict maintenance needs and optimize engine performance.

For instance, if a certain engine's twin indicates it's trending toward an exhaust gas temperature limit, maintenance can be scheduled at a convenient time before an in-flight issue occurs. While Rolls-Royce's public initiatives have focused on the digital twin and analytics side (under their TotalCare program), the immutable record aspect is a logical next step.

Blockchain could augment such engine digital twins by recording each maintenance event, part replacement, and software update throughout the engine's life in a tamper-proof log. This would add an extra layer of trust and traceability to Rolls-Royce's engine management service.

In the broader industry, companies like GE Aviation have also looked into blockchain for engine overhaul records. The synergy is clear: these high-value components benefit greatly from having both a real-time twin and a secure historical ledger.

GA Telesis

GA Telesis, one of the world's largest independent MRO providers, has developed a Blockchain and IoT-based platform for real-time aircraft component traceability across the commercial aviation industry. The system, which already holds a U.S. patent and is in active use within GA Telesis, creates a secure, immutable ledger of every part's lifecycle—from manufacturing and installation to maintenance and retirement.

By combining blockchain's tamper-proof recordkeeping with IoT sensor data, the platform enhances transparency, improves parts tracking, and supports predictive maintenance. GA Telesis aims to expand this solution to external industry partners, including airlines, OEMs, and lessors, offering a unified system that strengthens trust, simplifies audits, and improves operational efficiency.

Like GE Aviation, which has also explored blockchain for engine overhaul tracking, GA Telesis sees the synergy between digital twins and secure ledgers as key to transforming aviation asset management.

While many of these initiatives are in early stages or limited scopes (covering specific parts or single airline fleets), they provide valuable lessons. They show that the technology is viable and can integrate with existing operations. More importantly, they demonstrate enthusiasm among top-tier aviation companies to collaborate on data sharing when a robust trust mechanism is in place. As these pilot programs expand and converge, we can expect the use of digital twins and blockchain in aviation to become more commonplace.

Conclusion

Digital twins and blockchain are complementary technologies that together offer a powerful framework for managing aircraft throughout their entire lifespan. A digital twin provides the living, breathing model of an aircraft or component, enabling real-time monitoring and predictive insights. Blockchain provides the secure memory, ensuring every significant event in that model's life is recorded immutably and shared with those who need to know.

By linking the two, aviation stakeholders gain a single, trustworthy view of each asset – its current state and its complete history.

For aviation professionals, this means better decision-making and coordination: maintenance can be planned with foresight and verified data, regulators and lessors can rely on tamper-proof records, and no one has to hunt down missing information in an emergency or transaction. The benefits span from day-to-day efficiency (fewer delays and optimized maintenance) to long-term asset value and safety improvements.

An aircraft with a comprehensive digital twin and blockchain-backed logbook is simply a more transparent and reliable asset.

As the industry moves into this data-driven future, early projects by Boeing, Rolls-Royce, GA Telesis and startups lighting the path. Challenges remain – from standardizing data and achieving broad adoption to integrating with legacy systems – but the trajectory is clear.

In an era where trust in data is becoming as important as the aircraft itself, the combination of digital twins and blockchain is poised to redefine aviation asset management. Stakeholders who invest in these technologies can gain a competitive edge through improved uptime, lower costs, and enhanced trust with partners and customers.

The vision of seamlessly managing "aviation digital twins" with a blockchain aircraft maintenance ledger is no longer theoretical; it's being built now, promising a future where every aircraft's story is fully digital, securely stored, and readily accessible – from day one to retirement.

Ultimately, managing the complete lifecycle of aircraft data in this way will help the aviation industry fly safer, smarter, and more efficiently for decades to come.