Aviation is a heavily regulated industry, with safety authorities like the U.S. Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) enforcing strict aircraft documentation standards. Both regulators require comprehensive records for every aircraft part and maintenance action to prove airworthiness.

The Regulatory Documentation Challenge in Aviation

FAA guidelines emphasize verifying the traceability of all received parts by checking their certifications, test reports, and other records. Airlines and repair stations must keep detailed logs of inspections, repairs, and life-limited parts status to remain in FAA compliance. Meanwhile, EASA regulations explicitly mandate rigorous record-keeping: under EASA Part-M and Part-145, operators and maintenance organizations must retain detailed continuing airworthiness records (e.g. maintenance history, flight hours, and component lifespans) and ensure every part is traceable to an approved source.

In short, both FAA and EASA expect a verifiable "paper trail" for each component's origin, certification (FAA 8130-3 or EASA Form 1 release certificates), and usage history.

Current System Challenges

Despite these aligned goals, traditional compliance practices struggle under the paperwork burden. Current documentation systems are often fragmented and manual. Maintenance records may be spread across dozens of databases and paper files at airlines, manufacturers, and repair shops. According to industry studies, critical aircraft data is commonly scattered across up to 40 different systems among various stakeholders.

This fragmentation makes it difficult to verify traceability quickly or to assemble all required records during an audit. Worse, paper-based documents can be lost or easily forged. A stark example was the 2023 AOG Technics scandal, where a rogue supplier sold counterfeit engine parts using forged EASA Form 1 certificates.

- Over 70 falsified certificates were discovered

- 80% of fake parts came with forged paperwork lacking digital authentication

- Airlines had to ground aircraft and 12,000+ engines required urgent inspections

- Regulators issued emergency directives and tightened oversight

Blockchain and Aviation Records: A New Compliance Paradigm

Blockchain technology offers a compelling solution to these documentation challenges. At its core, a blockchain is a decentralized digital ledger that records transactions or data in secure, time-stamped blocks. Once added, records become part of an immutable chain that is tamper-proof and transparent to authorized users.

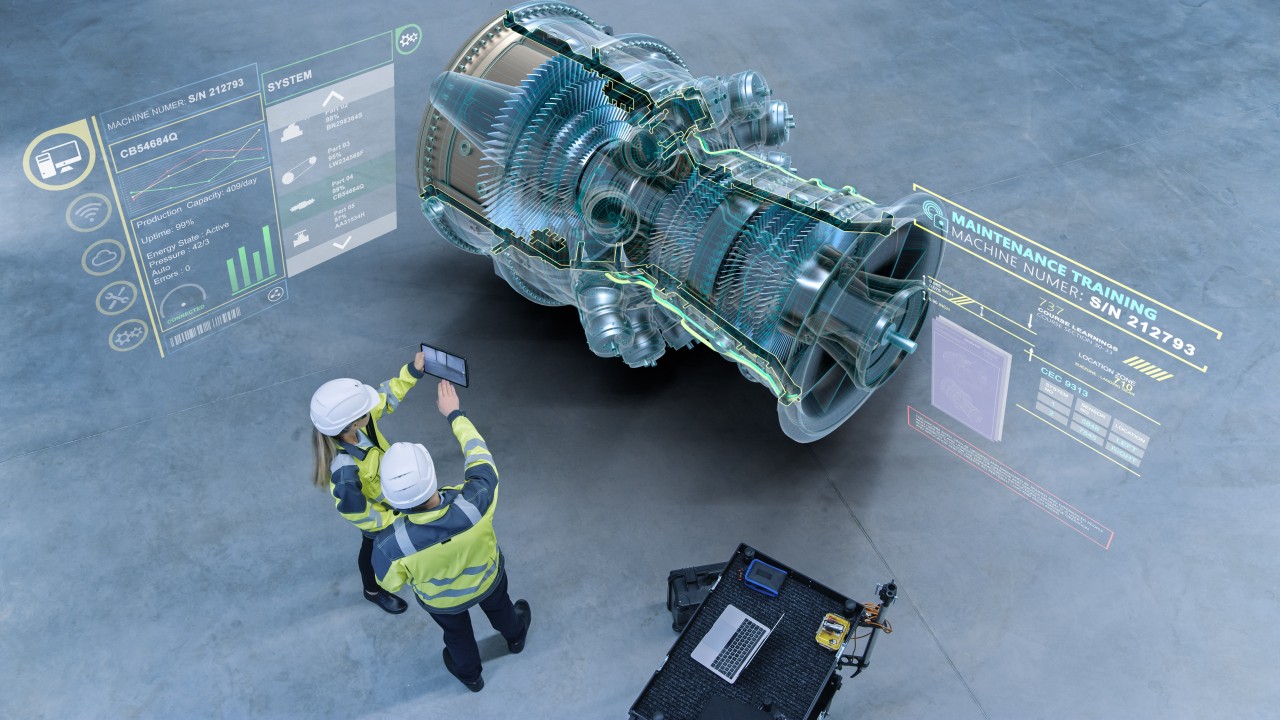

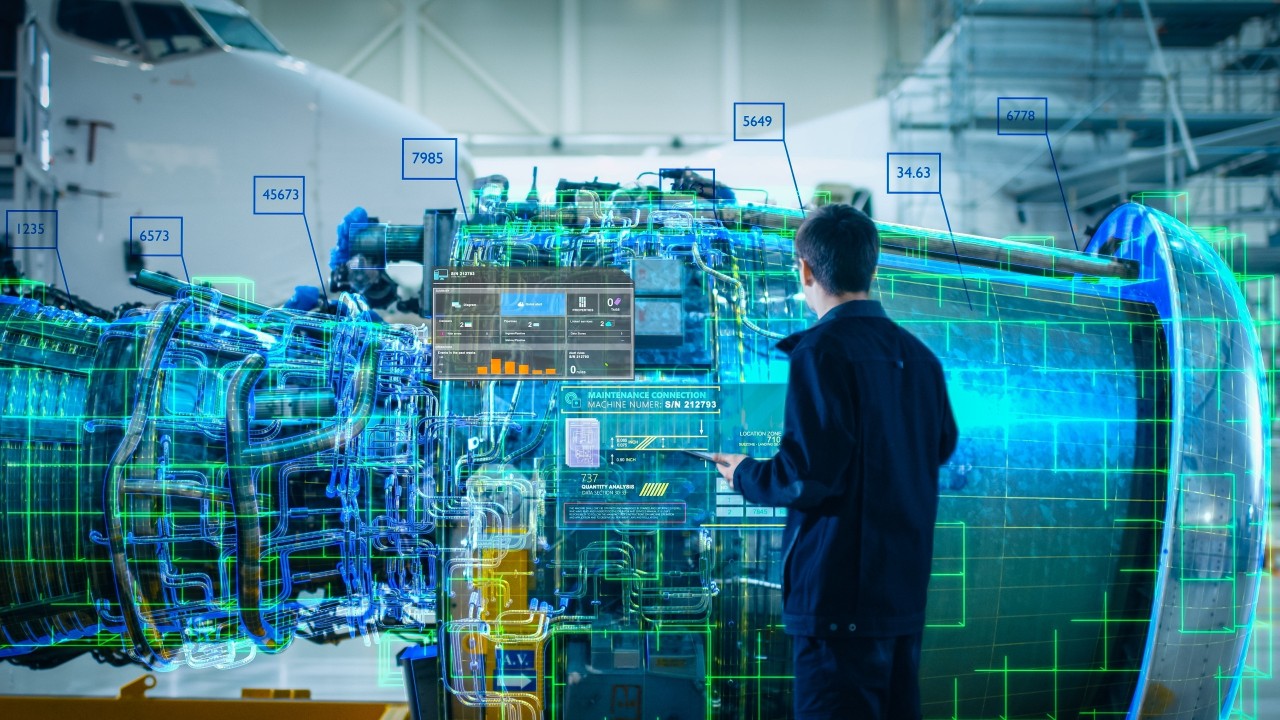

In aviation, this means a blockchain-based aviation record system can permanently track the full lifecycle of a part – from manufacture and certification to installation, maintenance, and ultimately retirement. Every update (such as a repair, inspection, or ownership change) is cryptographically logged and visible to approved stakeholders in real time.

Key Benefits of Blockchain Aviation Records

Tamper-Proof Documentation

Blockchain ledgers are immutable – once a maintenance event or certification is recorded, it cannot be altered or deleted without detection. This provides a level of record integrity far beyond paper files. Regulators require that records be protected against loss, destruction, or alteration, and a properly implemented blockchain inherently meets this standard by design.

End-to-End Traceability

Every part can be assigned a unique digital identity on the blockchain, with its entire history linked. This back-to-birth traceability means all data – origin, manufacturing lot, certifications, transfers, repairs, and even usage cycles – is chained together. EASA's traceability requirements for continuing airworthiness can be satisfied on a unified ledger that stakeholders update collaboratively.

Real-Time Authenticity Verification

Using blockchain, an airline or MRO can instantly confirm a part's approvals and documentation status. When a part is repaired or inspected, the authorized release certificate (FAA 8130-3 or EASA Form 1) could be digitally signed and logged on-chain. Later, any buyer or regulator can retrieve that record to verify the certificate's authenticity and the part's airworthiness status.

Honeywell Aerospace demonstrated this advantage: it now logs the actual FAA airworthiness form data for each part into a permissioned blockchain, enabling customers to simply enter a part number/serial and retrieve a digitally "reconstructed" certificate if the original paperwork is missing.

Audit Readiness and Efficiency

By consolidating records, blockchain greatly reduces administrative burden. Compliance officers and auditors can query the ledger for required information without sifting through binders or disparate IT systems. One blockchain project lead likened this to a "search engine for anything and everything related to aircraft parts and service".

Smart contract logic can be used to automate compliance checks – for example, flagging a component whose certification is expired or usage exceeds limits, triggering an alert before a regulatory violation occurs.

Security and Data Integrity

Modern blockchain platforms can be permissioned (private) networks, meaning only authorized aviation ecosystem members participate. Within such a network, sensitive data is protected via encryption, and each participant's identity is authenticated. This addresses concerns of proprietary or personal data exposure while still allowing controlled transparency.

Meeting FAA & EASA Requirements with Blockchain: Real-World Examples

What does blockchain-based compliance look like in practice? A number of aviation organizations have begun to answer this question, with pilot programs and early deployments that target FAA and EASA requirements:

EASA's VIRTUA Project – Pan-European Parts Tracking

In 2023, EASA launched a flagship initiative to leverage blockchain for traceability of aircraft parts across Europe. Dubbed Project VIRTUA, it brings together industry players to create a distributed ledger of approved aviation parts. The goal is to crack down on unapproved parts by listing every certified part on a tamper-proof ledger.

Prospective buyers or maintenance providers will be able to confirm a part's authenticity and certification status via the blockchain before installing it. By capturing the "whole lifecycle of certificates" – from a part's production and release by an OEM, through any design changes or repairs – the system aims to give regulators and operators a comprehensive, real-time view of compliance status.

This EASA-backed project reflects a broader regulatory trend in the EU toward digital verification; while not yet a formal mandate, it signals that blockchain traceability may soon become an expected standard for EASA compliance. As IATA's Senior VP Nick Careen noted, the hope is to create a vision of how blockchain solutions can address the parts authenticity issue plaguing aviation.

Honeywell GoDirect Trade – Digitizing Documentation

Honeywell Aerospace, a major OEM and parts supplier, has been a pioneer in applying blockchain to aviation record-keeping. Honeywell's GoDirect Trade platform is an online marketplace for new and used aircraft parts that uses blockchain to verify parts documentation in every listing.

Every part uploaded for sale is accompanied by its quality documents (maintenance logs, airworthiness certificates, etc.) which are hashed and stored on Honeywell's permissioned blockchain. This gives buyers confidence that the documents are genuine and correspond exactly to the part being offered.

Beyond the marketplace, Honeywell integrated blockchain into its internal repair and manufacturing record systems. Now, each time Honeywell produces or services a part, the event (along with its FAA certification details) is written to the ledger. The blockchain holds the form data from FAA 8130-3 certificates and other trace documents, not just references.

This means an airline customer who misplaces a piece of paper can input a part number and serial number into Honeywell's system and instantly retrieve the authoritative data to regenerate the certificate. Such capability directly addresses FAA and EASA documentation requirements by supplementing the physical documents with an unalterable digital backup.

Honeywell reports that over 7,000 users now leverage this system, and it has transformed audit readiness – what used to be a laborious search through filing cabinets can now be done with a quick blockchain query. As Lisa Butters, who leads the project, put it: this approach "simplifies and transforms record-keeping for aircraft owners and airlines" while building trust through transparency.

Airlines and MROs – Collaborative Ledgers

Airlines and maintenance, repair, and overhaul organizations (MROs) are also piloting blockchain to share and verify records. For example, Cathay Pacific Airways and its MRO partner HAECO, in collaboration with SITA, ran a pilot where aircraft parts were tracked on a blockchain from removal to storage to re-installation.

Each movement and maintenance action was logged, creating a continuous chain of custody that could be audited at any time. The aim was to eliminate fraudulent parts swaps and to streamline regulatory audits by having a ready-made digital logbook.

In another case, Air France–KLM Engineering & Maintenance (AFI KLM E&M) partnered with Parker Aerospace to implement a blockchain system that assigns each component a digital record of its manufacturing details, usage, and repairs. While these systems are typically private (unlike public cryptocurrency blockchains), they function similarly by giving each part a unique, verifiable identity and an ongoing history.

Notably, these digital part histories act much like an NFT (non-fungible token) in concept – they are unique, tamper-proof records of authenticity and ownership – but are kept in closed networks for security and compliance reasons. The results from early trials indicate significantly improved efficiency in EASA traceability checks and FAA record-keeping.

For instance, one report noted that a major airframer's blockchain platform cut counterfeit part incidents by over 60% after embedding tamper-proof QR codes linked to blockchain records on components (demonstrating how quickly verifiable records can deter the use of suspect parts).

Boeing's Digital Passport for Parts

Aircraft manufacturers are also preparing for a blockchain-enhanced future. Boeing, in response to industry pressures, has been working on digitizing its authorized release certificates (8130-3 forms). A recent industry coalition report highlighted a Boeing pilot project to create a digitally signed and authenticated 8130-3 certificate that can be exchanged through a secure digital medium.

Boeing's vision is to ensure there is "immutable evidence of the source and authenticity" of documents for every part in its supply chain – language that strongly echoes blockchain principles. By moving away from trusting ink signatures on paper to cryptographically assured digital signatures, Boeing expects to enhance quality and safety while meeting regulators' demands for reliability.

This kind of digital part passport could eventually integrate with an industry-wide blockchain, so that each new part comes with an incorruptible, traceable record "born" with it. The fact that Boeing is investing in these capabilities signals that even legacy compliance processes are set to evolve, likely incorporating distributed ledger technology to assure regulators that no part falls through the cracks.

GA Telesis

GA Telesis, one of the world's largest independent MRO providers, has developed a Blockchain and IoT-based platform for real-time aircraft component traceability across the commercial aviation industry. The system, which already holds a U.S. patent and is in active use within GA Telesis, creates a secure, immutable ledger of every part's lifecycle—from manufacturing and installation to maintenance and retirement.

By combining blockchain's tamper-proof recordkeeping with IoT sensor data, the platform enhances transparency, improves parts tracking, and supports predictive maintenance. GA Telesis aims to expand this solution to external industry partners, including airlines, OEMs, and lessors, offering a unified system that strengthens trust, simplifies audits, and improves operational efficiency.

Like GE Aviation, which has also explored blockchain for engine overhaul tracking, GA Telesis sees the synergy between digital twins and secure ledgers as key to transforming aviation asset management.

The Future of Aviation Compliance

In an industry where safety is paramount, the burden of compliance documentation is a necessary responsibility – but it doesn't have to be an inefficient one. Blockchain technology is emerging as a powerful tool to ease regulatory burdens for aviation professionals by modernizing how records are managed and shared.

By creating a single, immutable ledger for aviation records, blockchain removes many of the pain points that compliance officers, airlines, lessors, and MROs face with traditional record-keeping. It provides regulators like the FAA and EASA with greater confidence that the data they see is authentic, complete, and tamper-proof.

Benefits for Aviation Businesses

- Improved Audit Readiness: Audits become faster and less disruptive when you can instantly retrieve any maintenance log or certificate requested

- Stronger Defense Against Counterfeit Parts: Every component's pedigree can be verified on-chain

- Enhanced Transparency: All stakeholders have access to the same trusted records

- Reduced Administrative Burden: Less manual effort, fewer errors, greater efficiency

Conclusion: Toward Streamlined Compliance and Safer Skies

As regulators push for digital solutions (with EASA explicitly piloting blockchain and the FAA increasing scrutiny on traceability), the aviation industry has a clear opportunity to get ahead of the curve. Embracing blockchain aviation records now can help organizations ensure FAA compliance and EASA traceability with less manual effort, fewer errors, and greater transparency.

The result is a win–win: smoother compliance processes for the industry, and enhanced safety and trust for everyone who flies. The examples from current aircraft programs show that this isn't just theoretical: blockchain is already being applied to make compliance more robust and efficient in real-world scenarios.